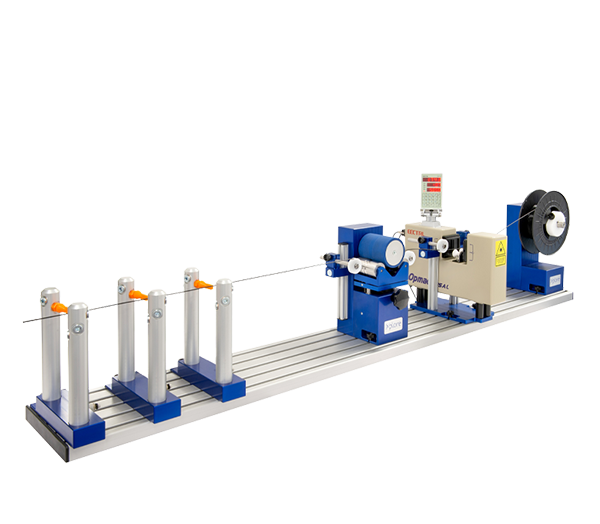

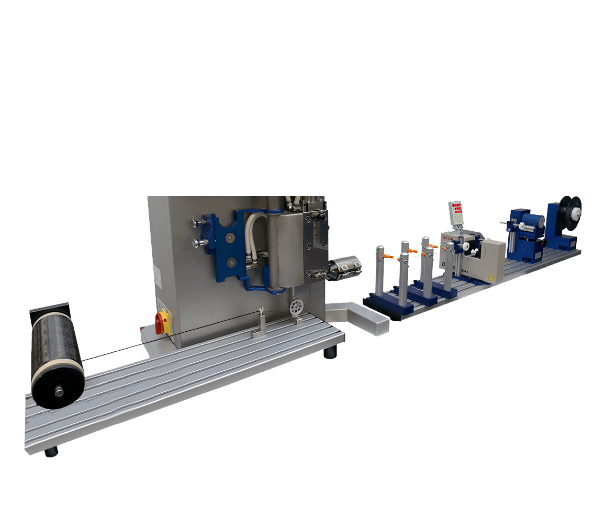

Tow Impregnation Die (TID)

The challenge with coating multifilament fiber bundles is that, ideally, each filament should be wetted with a molten polymeric material to prevent inconsistencies in material properties, which could lead to premature failure due to stress localization in the end product. The Xplore Tow Impregnation Die spreads a fiber bundle inside the die, allowing the molten polymeric material to penetrate between each filament, wetting each thread individually. Once Xplore masters the impregnation of fiber bundles, coating them becomes relatively straightforward since it is no longer necessary to spread each individual filament. The coating die consists of exchangeable inner sleeves that can be custom-tailored to specific diameters. This flexibility allows for the coating of any fiber bundle with the correct amount of polymer, offering a wide range of operating possibilities. Additionally, the die includes a threaded hole for connecting a pressure transducer. This feature enables precise control of the coating process through pressure adjustments.

Custom Design

The coating die features interchangeable inner sleeves that can be customized to fit various diameters. This flexibility allows you to apply the precise amount of polymer to any fiber bundle, offering a wide range of operational possibilities. Additionally, a threaded hole is provided to connect a pressure transducer to the coating die, enabling accurate control of the coating process based on pressure. This ensures optimal performance and consistency during production.