CFPL (Cast Film Pro Line)

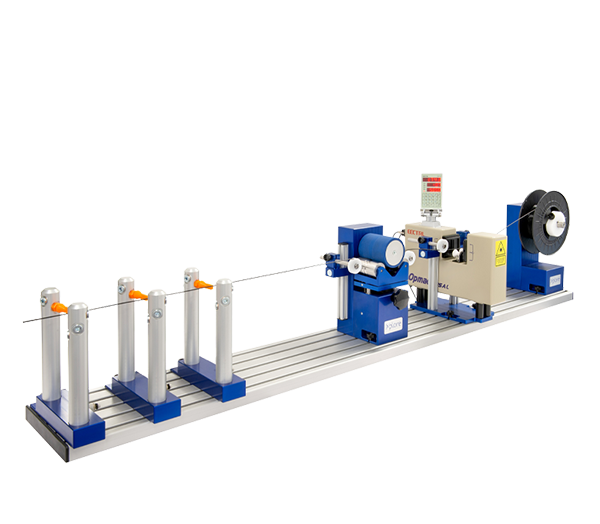

Xplore has developed a high-end Cast Film Pro Line (CFPL) featuring three calenders, offering extensive R&D capabilities. The CFPL ensures precise process control for testing and optimizing film formulations, particularly those with specialized properties such as optical clarity, mechanical strength, or barrier performance. In under 10 minutes, you can produce wide cast films using our heated film die, achieving thicknesses from as thin as 5 µm up to strip thicknesses, all from a batch created with one of our compounders. Alternatively, the CFPL allows you to produce continuous rolls of film or strips with larger sample quantities. With the CFPL, you can test and refine slippery film formulations more effectively, minimizing waste and costs. Its efficiency enables the production of over 20 unique film samples per day, making it an invaluable tool for research and development.

The film cast speed can be precisely adjusted on the first calender winder roll between 100 and 5000 mm/min, with fine increments of 1 mm/min enabled by micro-stepping technology. To minimize film necking, an air knife positioned just after the die, along with two air pins, ensures stable film formation. The second transport calender roll is also speed-controlled through a master-slave arrangement with the first calender, and features a pinch roll that adjusts mechanical pressure on the film sample to reduce slippage during processing. The third collecting calender winder roll operates under torque control, automatically adjusting to the growing film roll diameter during test runs to maintain even film uptake, with tension adjustments possible in 1 Nmm increments. Additionally, the system includes a continuous feeding kit with a mountable, water-cooled top hopper and dual continuous or forced feeding screws, allowing for automated feeding in continuous extrusion mode when connected to Xplore’s MC 15 HT or MC 5 micro compounders, enhancing efficiency and process control.