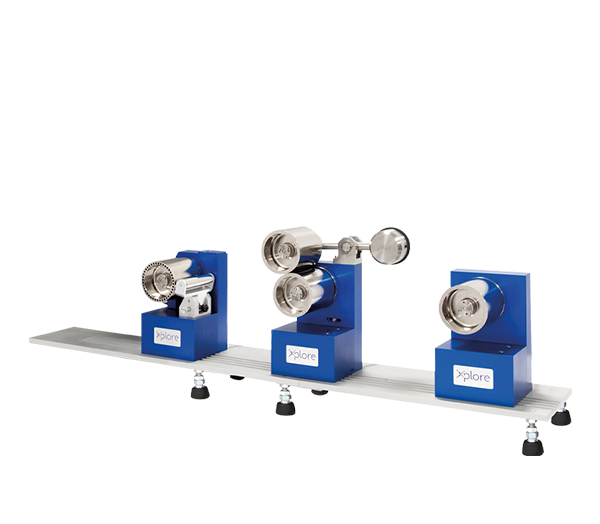

Micro Cast Film Lines

Looking for a small-scale, reliable, and cost-efficient solution for polymer film screening? Our CFL 35, CFL 65, and CFPL cast film lines produce flawless cast films using just a few grams of material, making them ideal for R&D applications, new formulations, and high-value polymers or additives. Fully compatible with Xplore micro compounders, these cast film lines help reduce screening costs and accelerate research workflows. Designed for fast and efficient film production, they generate representative films within minutes, significantly streamlining the screening process. Compared to traditional film development, they use only a fraction of the material, making them particularly useful for active pharmaceutical ingredients and experimental polymer blends. Capable of processing films up to 65 mm wide, as thin as 5 µm, and in extended lengths, they offer maximum flexibility. Featuring slip-free film transport with additional calendars and customizable solutions to meet specific requirements, our cast film lines provide a versatile and precise approach to polymer film screening.

Key features

- The continuous feeding kit simplifies automatic feeding in continuous extrusion mode, featuring a mountable, water-cooled top hopper and two continuous or forced feeding screws for smooth and efficient operation.

- For enhanced cooling, the first take-up roll can be optionally air-cooled, improving film processing conditions.

- The film drawing speed is fully adjustable from 100 to 5000 mm/min in precise 1 mm/min increments, allowing for optimal control over film production.

- To prevent film necking, an air knife is positioned immediately after the die, ensuring uniform film quality. The torque-controlled second collecting drum winder adjusts to the increasing roll diameter during operation, ensuring consistent film uptake with fine-tuned tension control in 1 Nmm increments.

- This system offers greater efficiency, stability, and precision in film extrusion and winding, making it an essential solution for R&D and production applications.