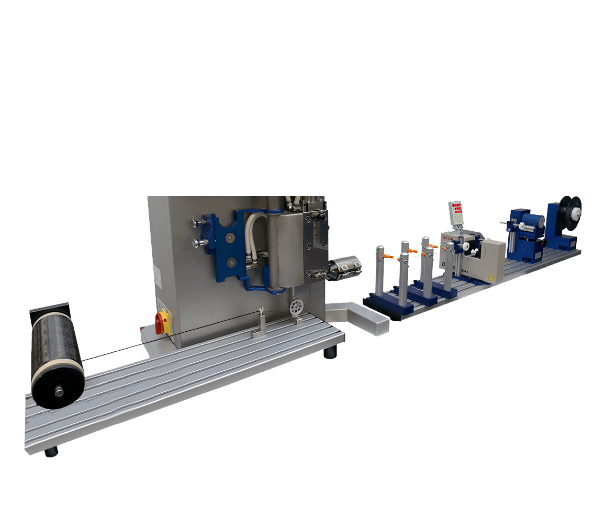

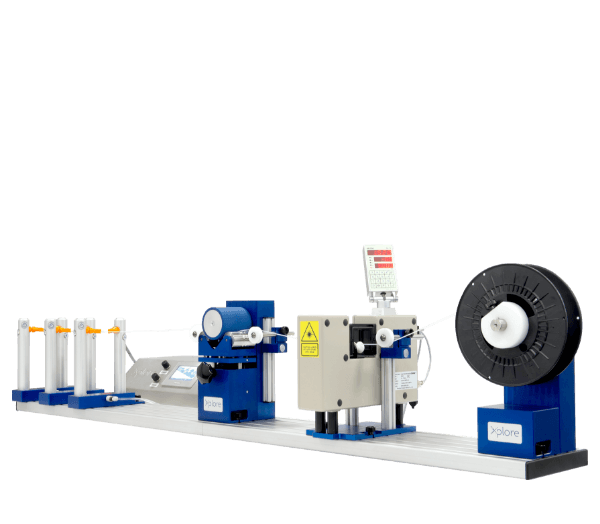

3D Filament Line

Xplore's 3D print filament line is designed to produce high-quality Fused Deposition Modeling (FDM) filaments with excellent dimensional stability from minimal material. This innovative R&D tool enables the development of experimental filament formulations, providing quick and reliable test results for further analysis. When connected to the Xplore MC 15 HT or MC 40 compounder, it transforms into a fully integrated 3D print filament screening system, streamlining filament composition research and feasibility studies. This filament line add-on offers a cost-effective, efficient solution for producing reliable and reproducible FDM filaments with minimal waste and reduced infrastructure costs. Its optional feeder ensures precise molten polymer throughput, maintaining consistent filament diameter and quality. With its ability to accelerate R&D efforts, reduce material usage, and enhance formulation testing, this must-have tool is an essential addition for researchers developing next-generation 3D printing materials.

Key Features

The melt torque measurement of our compounders, combined with a custom volumetric pellet or powder feeder, ensures pressure equilibrium within the primary processing barrel, delivering a constant throughput of the molten polymer at a given screw RPM. This provides an ideal starting point for processing 3D filaments for R&D without requiring an expensive gear pump, allowing for producing homogeneous, accurately dimensioned filaments free from voids. This system enables rapid screening of 3D filaments with different compositions using small material quantities, making feasibility studies fast and efficient. It is compatible with common FDM materials such as PLA, ABS and high temperature engineering materials like PC, PEEK, and PEI. It offers a wide range of line speeds and the ability to wind filaments onto standard industrial bobbins. Additionally, it can be retrofitted onto the Xplore MC 15 legacy micro-compounder, providing a cost-effective and time-saving solution for advanced 3D filament development.