Precise, efficient and safe R&D solutions

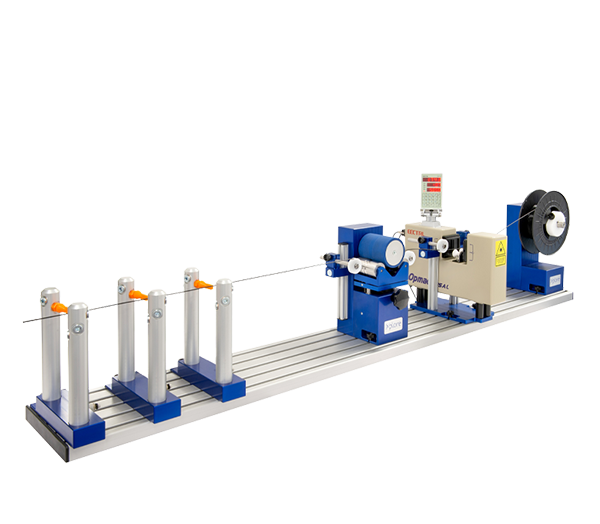

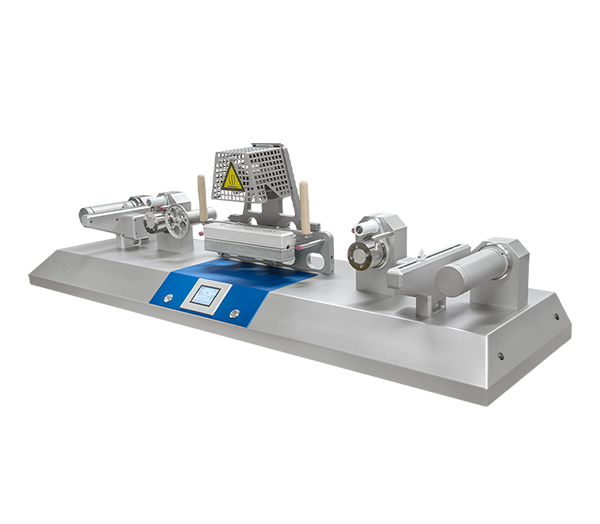

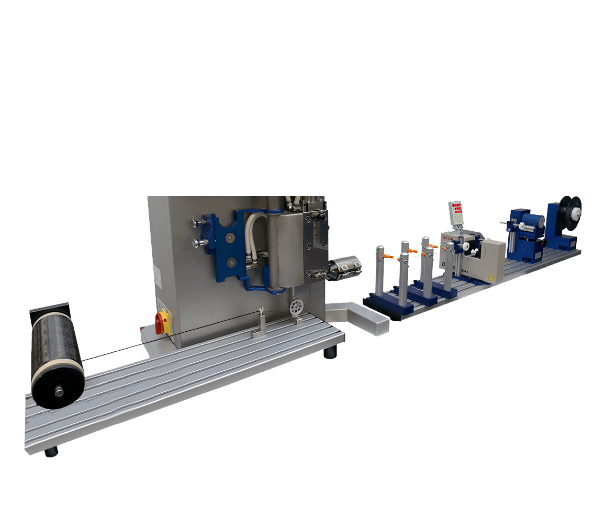

Xplore micro and lab compounders provide unmatched value and performance, surpassing traditional parallel twin-screw lab extruders in mixing efficiency, flexibility, and durability. With an extremely robust design, a lifespan of over 10 years, and precise control over processing conditions, these extruders deliver high reproducibility, scalability, and efficiency. Our Vari-Batch™ technology (2–40 ml sample volumes) enables early-stage material testing, reducing screening costs while allowing quick sample and screw exchange for diverse experiments. Key features include continuous screw torque monitoring, rapid in-line shaping (injection molding, films, filaments), and easy cleaning with water cooling and cleaning compounds, minimizing downtime between batches. The six-zone heating system and abrasion- and chemical-resistant barrels ensure long-term stability and accurate rheological data. Unlike competing extruders, Xplore systems can be seamlessly scaled up to larger parallel twin-screw extruders, making them suitable for both research and industrial applications. With more than 30 years of Dutch engineering expertise, Xplore’s next-generation micro compounders offer a fast, reliable, and cost-effective solution for formulation development, feasibility studies, and material screening. These innovative tools accelerate material innovation, helping researchers and industry professionals optimize processes and develop high-performance materials with ease.

High quality

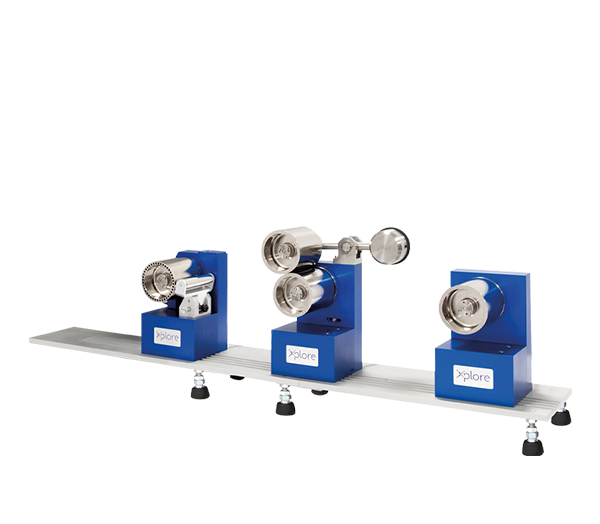

The robust design, incorporating high-quality components such as the motor drive, housing, barrel, and screws, ensures superior long-term reproducibility and a prolonged service life. The precision and material quality of these components enable consistent and reliable data generation over time, which is critical for maintaining the integrity of research. This level of quality also facilitates highly reproducible in-line downstream shaping processes, including injection molding, film extrusion, and (multi)filament processing.

Sustainability

The benefits include reduced sample material consumption, lower environmental impact due to minimized contamination, and limited operator health risk exposure. Additionally, the compact footprint ensures efficient use of lab space, optimizing overall laboratory resource utilization.

Want to know more about what product could fit your purpose?

Contact us