Explore the future of thermoplastic composites with Xplore—where innovation meets efficiency

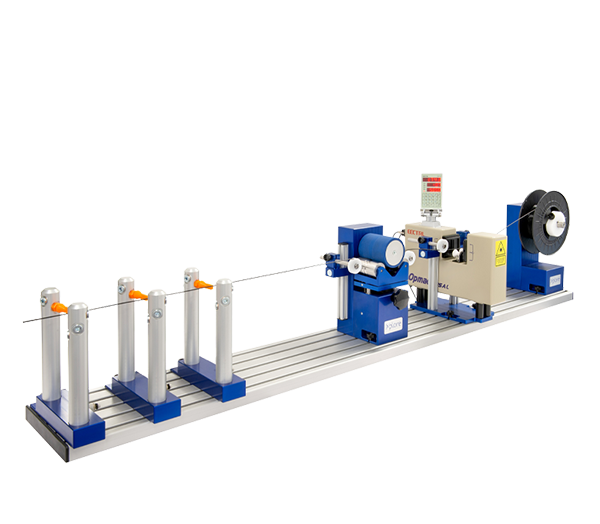

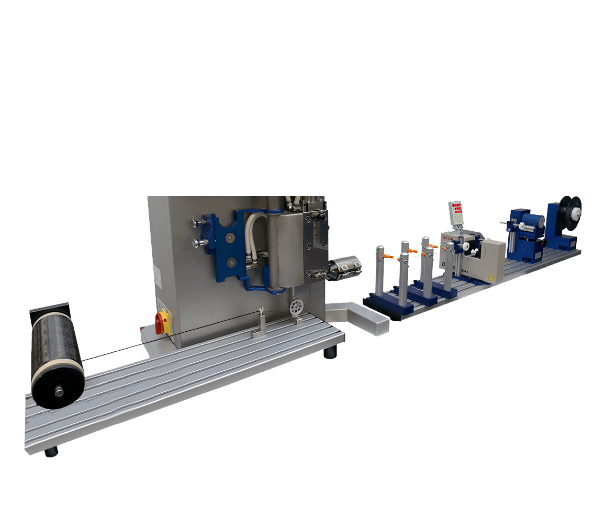

Thermoplastic composites are cutting-edge materials that combine a polymer matrix with reinforcing fibers, delivering superior strength, durability, and lightweight performance. A key advancement in this field is thermoplastic unidirectional (UD) tape technology, which utilizes continuous fiber reinforcement to achieve exceptional mechanical properties and structural integrity. These UD tapes offer high strength-to-weight ratios, excellent impact resistance, and improved recyclability, making them essential materials for industries such as aerospace, automotive, and sports equipment. Short fiber-reinforced thermoplastics feature randomly dispersed fibers, typically less than 1 mm long, enhancing stiffness, impact resistance, and ease of processing—making them ideal for injection molding applications. In contrast, long fiber-reinforced thermoplastics (LFRTs) contain longer chopped or continuous fibers (typically 10 mm or more), providing exceptional mechanical properties, higher strength-to-weight ratios, and enhanced load-bearing capabilities, making them perfect for structural applications in automotive, aerospace, and industrial sectors. Both SFRTs and LFRTs support sustainable manufacturing, as they are recyclable and enable energy-efficient production. At Xplore, we empower you to fast-track your research on material transition with our advanced micro-compounding solutions. Our MC15HT and MC40 micro-compounders allow you to efficiently compound materials or feed molten polymers into an impregnation die for continuous tow impregnation. With our coating die, you can rapidly screen various polymer formulations, enabling precise research on UD tape development using our micro-UD tape line. Additionally, when paired with our pro pelletizer, you can produce long fiber thermoplastic (LFT) composites in just minutes—customized with glass, carbon, or biofibers for superior performance.

Support

Xplore provides exceptional support for the polymer composite market, offering comprehensive resources like whitepapers, technical documents, FAQs, and expert guidance to optimize machine performance and streamline R&D processes.

Whitepapers Technical notes Specification sheets FAQ ContactBe inspired

Effect of barrel gap on the dispersion quality of carbon black in rubber compounds

What does it mean when you change the barrel screw gap in relation to distribution and dispersion of particles in a rubber matrix.

Read more

In-mold crosslinking of rubber compounds

The Xplore MC 15 HT high torque laboratory micro-compounder and IM 12 combo also offers high-viscous rubber processing capabilities.

Read more

Maintenance services

Xplore does offer maintenance services for your precious Xplore equipment, prolonging the machine’s lifetime and ensuring you are compliant.

Read more