Extruding the future of food innovation

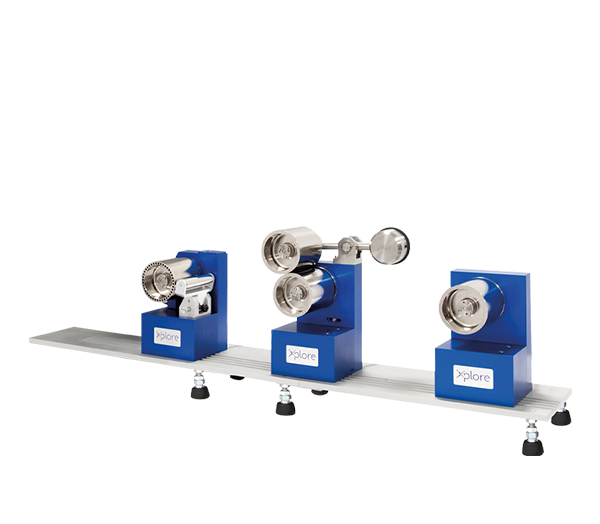

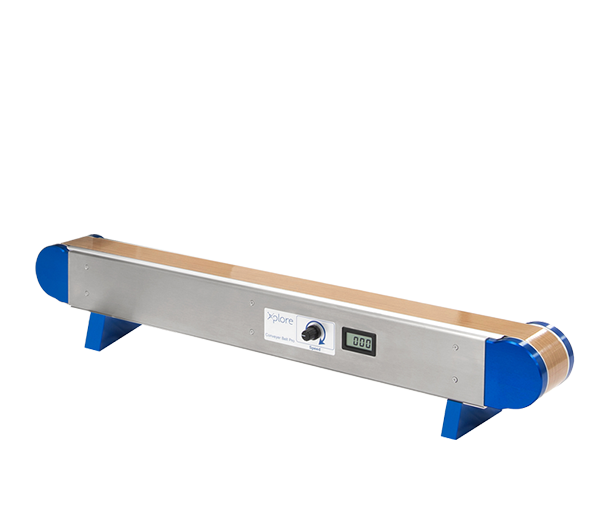

Extrusion technology is a pivotal process in developing nutritional products, including alternative proteins, human food, and animal feed. Extruders transform raw materials into structured, digestible, and nutrient-rich products while enhancing texture, nutritional value, and scalability by utilizing high-temperature, short-time processing. A key application is vegetable protein texturization, where extrusion modifies plant-based proteins such as soy, pea, and wheat gluten to create fibrous structures that mimic the texture of meat. This process is essential for developing high-quality meat analogs that meet consumer expectations for taste and mouthfeel. In food and feed production, extrusion also enables the formulation of cereals, snacks, pet food, and livestock feed with improved digestibility and nutrient uniformity. Xplore micro-compounders play a crucial role in early-stage formulation development by allowing precise testing with minimal material usage. These small-scale extruders help optimize ingredient combinations, refine protein structuring, and incorporate bioactive ingredients such as vitamins and probiotics before scaling up to larger production systems. Their versatility and efficiency make extrusion and micro-compounding essential tools for accelerating innovation in sustainable food and feed development.

Support

Xplore provides exceptional support for the nutrition market, offering comprehensive resources like whitepapers, technical documents, FAQs, and expert guidance to optimize machine performance and streamline R&D processes.

Whitepapers Technical notes Specification sheets FAQ ContactBe inspired

Effect of barrel gap on the dispersion quality of carbon black in rubber compounds

What does it mean when you change the barrel screw gap in relation to distribution and dispersion of particles in a rubber matrix.

Read more

In-mold crosslinking of rubber compounds

The Xplore MC 15 HT high torque laboratory micro-compounder and IM 12 combo also offers high-viscous rubber processing capabilities.

Read more

Maintenance services

Xplore does offer maintenance services for your precious Xplore equipment, prolonging the machine’s lifetime and ensuring you are compliant.

Read more