Rapid pathway from idea to innovation in biomedical material development

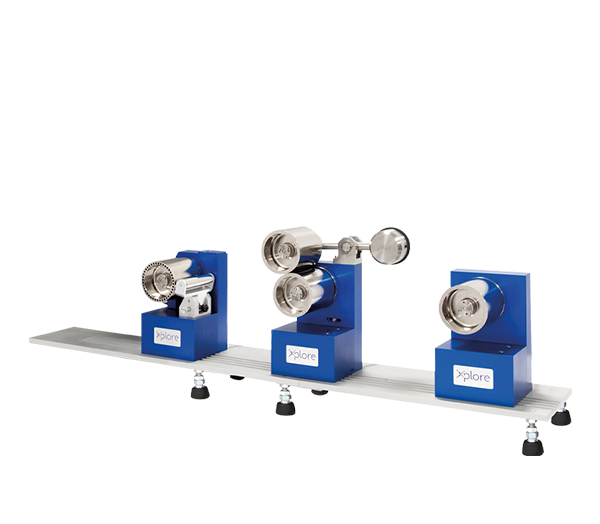

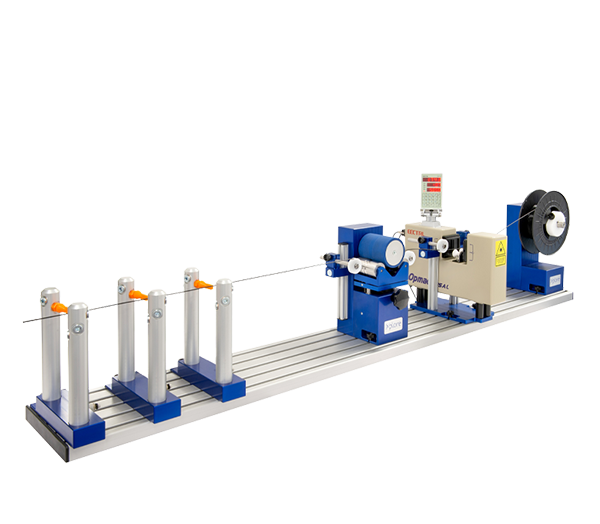

Developing advanced biomedical materials is crucial for improving medical devices, enhancing patient outcomes, and driving innovation in healthcare. High-quality polymers and composites play a vital role in creating durable, biocompatible, and efficient medical equipment. Precision and reliability in material processing are essential to meet these growing demands. The micro compounders offered for biomedical markets are designed for ease of use, robust performance, and high efficiency. They feature high screw torque, small working volume, and strong abrasion and chemical resistance, ensuring long-term reliability. The integrated rheological software enhances process control and scalability to larger extruders. These instruments are ideal for testing various plastic formulations for biomedical applications, allowing for rapid prototyping and performance screening. Additionally, a proprietary protocol supports reliable scale-up from small to larger twin-screw extruders, facilitating material development and new product innovation in the biomedical industry.

Support

Xplore provides exceptional support for the biomedical market, offering comprehensive resources like whitepapers, technical documents, FAQs, and expert guidance to optimize machine performance and streamline R&D processes.

Whitepapers Technical notes Specification sheets FAQ ContactBe inspired

Effect of barrel gap on the dispersion quality of carbon black in rubber compounds

What does it mean when you change the barrel screw gap in relation to distribution and dispersion of particles in a rubber matrix.

Read more

In-mold crosslinking of rubber compounds

The Xplore MC 15 HT high torque laboratory micro-compounder and IM 12 combo also offers high-viscous rubber processing capabilities.

Read more

Maintenance services

Xplore does offer maintenance services for your precious Xplore equipment, prolonging the machine’s lifetime and ensuring you are compliant.

Read more