Faster and more reliable R&D results

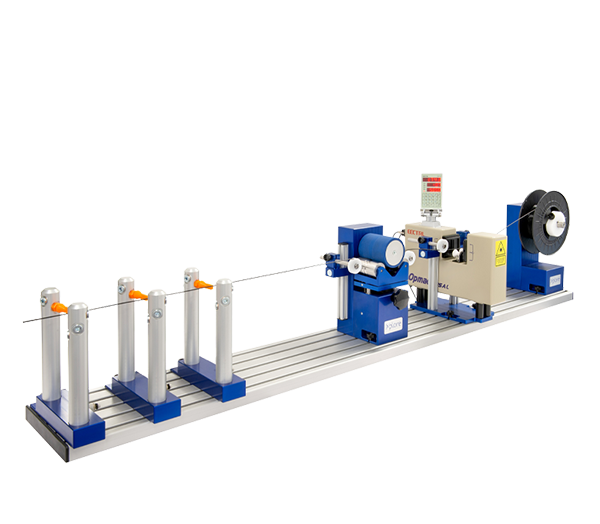

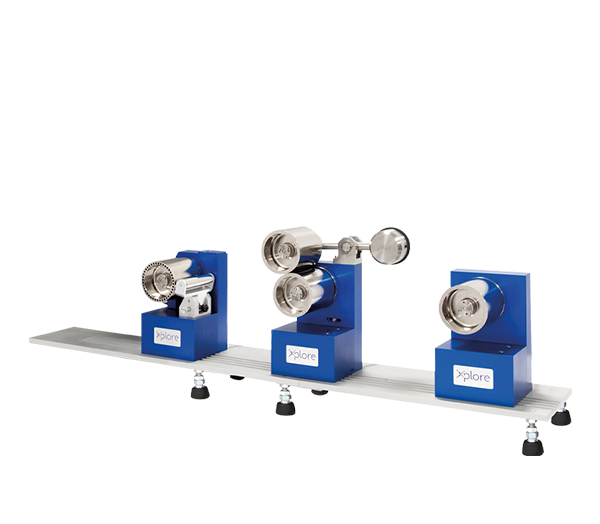

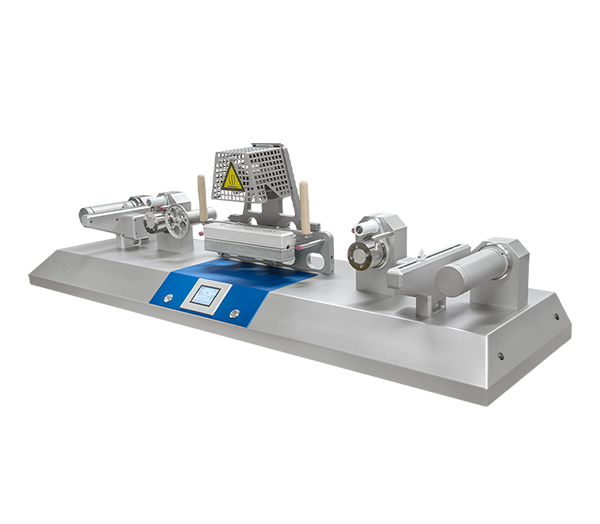

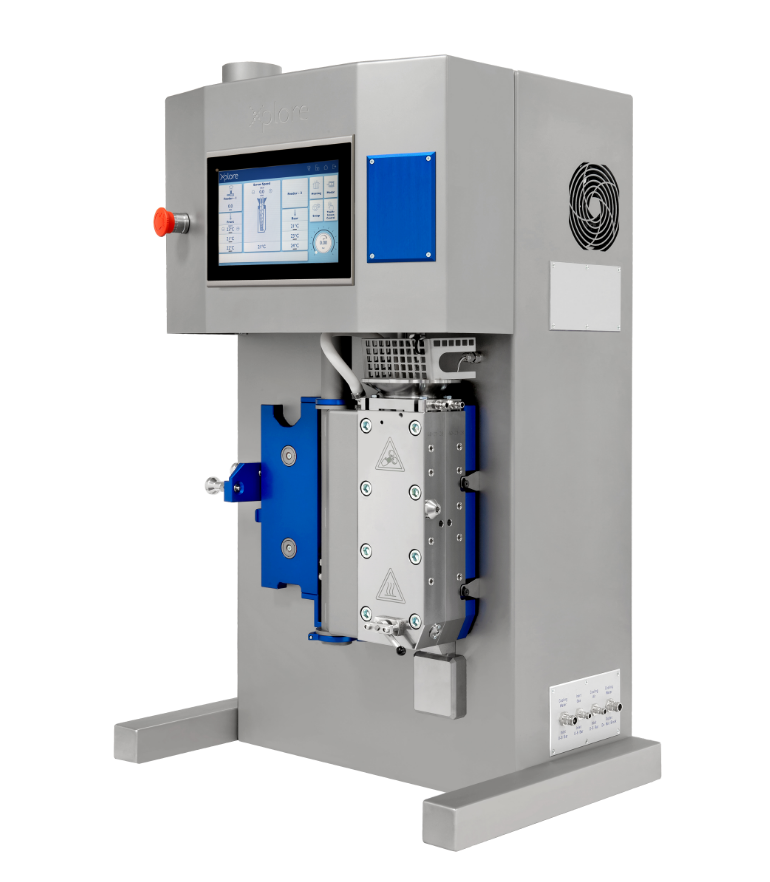

For over 30 years, Xplore has been a trusted name in micro-compounding instruments and downstream equipment, enabling scientists to drive polymer innovation with efficiency and minimal environmental impact. Designed to meet the rigorous demands of research and development, our instruments offer exceptional precision, reliability, and reproducibility at a lab-scale.With a minimal sample requirement, our systems provide robust results, while their user-centric design ensures ease of operation. The integration of advanced software delivers precise rheological data and critical scale-up factors, bridging the gap between lab-scale experimentation and production.Xplore Instruments are synonymous with quality and performance, supporting researchers in accelerating formulation development, conducting feasibility studies, and optimizing polymer screening processes. Partner with Xplore to achieve your innovation objectives in a cost-effective and time-efficient manner.

Our solution

Our Markets

Our cutting-edge instruments are designed to deliver exceptional benefits across a variety of markets. They are widely utilized for; formulation development, polymer screening, feasibility studies and quality control. Curious about what we can do for your market? Click on your market below to find out more.

See other Xplore instruments that enhance your research and development

View all productsBe inspired

How Continuous Feeders Improve Accuracy in Micro-Compounding?

Continuous micro-compounding feeding enables stable and reproducible polymer processing through precise pellet and powder dosing at lab scale.

Read more

Developing Medical (Micro)-Tubes for Biomedical Applications: Rapid Prototyping with Micro-Processing

How micro-compounding and micro-tube extrusion support rapid prototyping of precision medical tubing.

Read more

Enabling Shape Memory Biomedical Materials with Micro-Compounding

Explore shape memory polymers for biomedical devices, from PLA/TPU blends to compatibilization and micro-processing for reliable performance.

Read more

Experience our innovations

Does purchasing one of our instruments make sense? Do you want to check the latest model of our product portfolio? Or get a quotation for a maintenance contract?

We are always happy to arrange an online instrument demonstration or connect you with our local distributor.

Contact us